There are no products listed under this category.

Shop by Category

-

Wico Magneto RX

- AX Magneto Brochure

- B Magneto RX

- F Series: F,FG,FGM,FGS

- A Magneto RX

- Condenser Information

- EK Magneto Rx

- LD and H Magneto RX

- OC Wico Magneto

- R Magneto Ignitor RX

- XH and XHD Magneto RX

- AH Wico magneto Rx

- AP Magneto RX

- C Magneto RX

- FW Series: Flywheel Magneto Service Info

- H1 Magneto RX

- J4 Manual

- JEM Manual

- PR Magneto RX

- Wico Magneto 1946 Catalog

-

Wico Magneto Application Information

- XVD-4 and XVD-6

- Bendix

- Berling Magnetos

-

Bosch, American Bosch, and Robert Bosch

-

American Bosch

-

Am Bosch Mags Ca 1945 MJA MJB MJC MVA MJK

- MRA Magneto American Bosch

- MRF American Bosch Magneto

- DU1,DU2,DU4..Ad nauseum Bosch Catalog 50

- Flywheel Magnetos by American Bosch

- Impulse Coupler RX

- Instruction Book & Agents 1925 Am Bosch

- Service Manual American Bosch Magneto 1928

- ZR4 For Ingersoll Rand Compressor

- ZR4 ZR6 Instruction Manual

- AB 33 and some mumblings on the AB34

- Application Information

- AT4 AT6 Bosch Magneto Instruction Parts Manual

- B4 + B6 Manual

- Bosch Magneto Service Parts List 1922

- DU Service Manual

- FX1 American Bosch Magneto Parts List

- Home of the Bosch Magneto

- MRD Am Bosch Magneto Service Manual

- MVA American Bosch Magneto Instruction Manual

- U1 U2 U4 U6 Debut Whatsa Matter U?

- ZR4 Service manual

-

Am Bosch Mags Ca 1945 MJA MJB MJC MVA MJK

- Bosch

- Robert Bosch

-

American Bosch

-

Edison Magneto

-

Eisemann

- CM4/CT4 Eisemann Magneto Instructions

-

Flywheel Magnetos by Eisemann

- Eisemann 61-D flywheel magneto

- Eisemann 61Cflywheel Mag

- eisemann 61DA Flywheel magneto

- Eisemann 61DC flywheel magneto

- Eisemann 61DE Flywheel magneto

- Eisemann 61DF Flywheel magneto

- Eisemann 61DH Flywheel magneto

- Eisemann 61NA flywheel magneto

- Eisemann 62-D Flywheel magneto

- Eisemann 72C Flywheel Magneto

- Eisemann 72D Maytag Magneto

- Eisemann 72DA Maytag Magneto Service

- Eisemann 82-D and 82-F Flywheel Mags

- M4G6 Eisemann Magneto Generator

- AM Series

- Automatic Spark Control Early

- CM-4 Caterpillar Magneto Service + Parts Manual

- CT-4 Caterpillar Magneto Service & Parts Manual

- EB

- ED EU EA

- Eisemann Catalog 1920

- Eisemann Catalog with Accessories

- Eisemann catalog 1915

- Eisemann- Caterpillar Parts Info

- EM Dual

- EM for Model T Ford

- G0 G1 G2 Service and Parts Manual

- G4

- GL Series Service & Parts Manual

- GL1 GL2 GLF1 GLF2

- GL4 GL2H

- GN6 Edition 3 Manual

- GN6 Edition 4

- GR4 Ed 2 magneto parts&Service manual

- GS Series

- GV Series Service and Parts Manual

- GV-4 GV-2H GV-2Q

- GV-6 Eisemann magneto

- RC/RT Series

-

Fairbanks Morse

- Fairbanks Morse Illustrated parts 1983 Sec 4

- Fairbanks Morse Magneto Application Information

- Fairbanks Morse Model "R" RX

- FM FM-H FM-K FMO FM-OH Heavy Duty Series RX

- FM-J1A.. FM-J1B.. Radio Shld 9864A

- FMJ Series Parts List 1947 Bulletin 9846B

- FMJ1A Instructions 1947 Bulletin 2888B

- FMJ1A.. FMJ1B.. 1947 Bulletin 2864B

- FMJ2 Series 2854C

- FMJ4A,B Instructions 1942 Bulletin 2846A

- FMJH Series: Mercury/Disston/Kiekhafer 9871A

- FMJV4B Wisconsin V4 Engine

- FMX. Series: AKA the Updated FMJ series

- Magnetizing Fairbanks Morse Magnetos

- RV RX

- Heinze AX & BX Magneto

- Ignition and Truck Profits

- International Harvester Magneto Rx

-

K-W Ignition Company Magnetos

- K-W Ignition Magneto Instruction Book 3Rd Ed

- K-W Low tension Magnetos catalog 19

- K-W Model J Magneto Manual

- K-W Model T and TK Magneto Instruction Book

- K-W O F Oscillating Magneto Manual

- K-W T TK TU TUK Magneto Catalog Ed 8

- K-W T TK TU TUK Magneto Manual Edition 6

- KW Magneto Promo What Makes Tractor Go?

- Perfection Magneto Company

- Pittsfield type B Magneto

- Remy

- Simms Magneto

- Simms Motor Units Catalog 1940

-

Splitdorf

- C Magneto Specifications

- C Magneto manual

-

Dixie and Aero Magnetos

- Dixie 46 246 462 Magneto Parts List

- Aero 448 449 648 649 Magneto

- Aero AE Magneto Manual

- Aero Magneto Catalog 1925

- Dixie 235 Oscillating Magneto

- Dixie 40 42 and 44 Magneto Manual N-404A 1919

- Dixie 46 Magneto Manual N-403C 1919

- Dixie 8 Cylinder Magnetos #83-86

- Dixie Aero Service Info

- Dixie Magneto Model 60 and 63 Catalog 1915

- Dixie Splitdorf Magneto Catalog N-401

- Splitdorf 46T and EM Impulse Starter

- Splitdorf Dixie M1 & M2 Magneto

- NS-1-2550 Magneto parts List

- NS-2 Magneto Parts list

- NS-4 Magneto parts List

- S-2 Magneto Parts List

- S-4 Magneto parts List

- SS-4 Magneto Parts List

- SS-6 Magneto Parts List

- SS-6-2 Magneto Parts List

- SSO Magneto Parts List

- AE

- Cross Country On Motorcycle

- NS Motorcycle Magneto Manual

- S NS SS B Magneto Service Manual

- Splitdorf Apelco Starting Lighting

- Splitdorf catalog 1910

- Splitdorf catalog 51 1913

- Splitdorf Magneto catalog 52 1914

- Splitdorf Magneto catalog 53 Models EU & EV

- Splitdorf Magneto catalog 57 1914

- Splitdorf Wiring Diagrams 1914

- U & V Splitdorf Magneto manual 1912

- Sumter Magneto Rx

- Webster

-

Wico Magneto RX

- AX Magneto Brochure

- B Magneto RX

- F Series: F,FG,FGM,FGS

- A Magneto RX

- Condenser Information

- EK Magneto Rx

- LD and H Magneto RX

- OC Wico Magneto

- R Magneto Ignitor RX

- XH and XHD Magneto RX

- AH Wico magneto Rx

- AP Magneto RX

- C Magneto RX

- FW Series: Flywheel Magneto Service Info

- H1 Magneto RX

- J4 Manual

- JEM Manual

- PR Magneto RX

- Wico Magneto 1946 Catalog

- Wico Magneto Application Information

- XVD-4 and XVD-6

- Bendix

- Berling Magnetos

- Bosch, American Bosch, and Robert Bosch

- Edison Magneto

-

Eisemann

- CM4/CT4 Eisemann Magneto Instructions

- Flywheel Magnetos by Eisemann

- M4G6 Eisemann Magneto Generator

- AM Series

- Automatic Spark Control Early

- CM-4 Caterpillar Magneto Service + Parts Manual

- CT-4 Caterpillar Magneto Service & Parts Manual

- EB

- ED EU EA

- Eisemann Catalog 1920

- Eisemann Catalog with Accessories

- Eisemann catalog 1915

- Eisemann- Caterpillar Parts Info

- EM Dual

- EM for Model T Ford

- G0 G1 G2 Service and Parts Manual

- G4

- GL Series Service & Parts Manual

- GL1 GL2 GLF1 GLF2

- GL4 GL2H

- GN6 Edition 3 Manual

- GN6 Edition 4

- GR4 Ed 2 magneto parts&Service manual

- GS Series

- GV Series Service and Parts Manual

- GV-4 GV-2H GV-2Q

- GV-6 Eisemann magneto

- RC/RT Series

-

Fairbanks Morse

- Fairbanks Morse Illustrated parts 1983 Sec 4

- Fairbanks Morse Magneto Application Information

- Fairbanks Morse Model "R" RX

- FM FM-H FM-K FMO FM-OH Heavy Duty Series RX

- FM-J1A.. FM-J1B.. Radio Shld 9864A

- FMJ Series Parts List 1947 Bulletin 9846B

- FMJ1A Instructions 1947 Bulletin 2888B

- FMJ1A.. FMJ1B.. 1947 Bulletin 2864B

- FMJ2 Series 2854C

- FMJ4A,B Instructions 1942 Bulletin 2846A

- FMJH Series: Mercury/Disston/Kiekhafer 9871A

- FMJV4B Wisconsin V4 Engine

- FMX. Series: AKA the Updated FMJ series

- Magnetizing Fairbanks Morse Magnetos

- RV RX

- Heinze AX & BX Magneto

- Ignition and Truck Profits

- International Harvester Magneto Rx

-

K-W Ignition Company Magnetos

- K-W Ignition Magneto Instruction Book 3Rd Ed

- K-W Low tension Magnetos catalog 19

- K-W Model J Magneto Manual

- K-W Model T and TK Magneto Instruction Book

- K-W O F Oscillating Magneto Manual

- K-W T TK TU TUK Magneto Catalog Ed 8

- K-W T TK TU TUK Magneto Manual Edition 6

- KW Magneto Promo What Makes Tractor Go?

- Perfection Magneto Company

- Pittsfield type B Magneto

- Remy

- Simms Magneto

- Simms Motor Units Catalog 1940

-

Splitdorf

- C Magneto Specifications

- C Magneto manual

- Dixie and Aero Magnetos

- NS-1-2550 Magneto parts List

- NS-2 Magneto Parts list

- NS-4 Magneto parts List

- S-2 Magneto Parts List

- S-4 Magneto parts List

- SS-4 Magneto Parts List

- SS-6 Magneto Parts List

- SS-6-2 Magneto Parts List

- SSO Magneto Parts List

- AE

- Cross Country On Motorcycle

- NS Motorcycle Magneto Manual

- S NS SS B Magneto Service Manual

- Splitdorf Apelco Starting Lighting

- Splitdorf catalog 1910

- Splitdorf catalog 51 1913

- Splitdorf Magneto catalog 52 1914

- Splitdorf Magneto catalog 53 Models EU & EV

- Splitdorf Magneto catalog 57 1914

- Splitdorf Wiring Diagrams 1914

- U & V Splitdorf Magneto manual 1912

- Sumter Magneto Rx

- Webster

- Home

- Magneto Rx:

- Fairbanks Morse

- FMX. Series: AKA the Updated FMJ series

- FM-XD1B7 3059WA for Wisconsin 1 banger

FM-XD1B7 3059WA for Wisconsin 1 banger

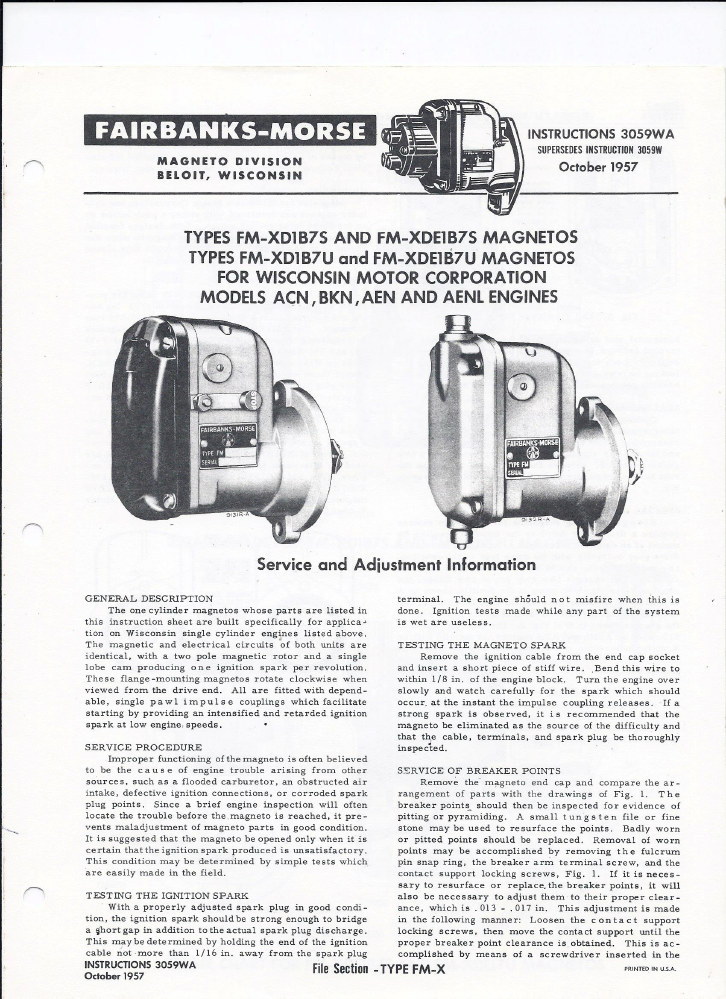

The FM-XD1B7 is a single cylinder special flange mounted device used extensively by Wisconsin Motors . It bears a lot of similarities to is predecessor, the FMJ series but uses a different breaker and a vent. This is a reliable and serviceable magneto that is robustly designed like the Wisconsin engines. Here is some service information to keep yours on line by kind permission from Fairbanks-Morse.

The first step before a frontal assault on the magneto is to test the spark as described above. The most difficult and costly repairs to make are those to a device not needing them. Many causes of ignition failure can be traced to improper plugs and wires (resistor plugs and wires are a big NO NO and can damage the coil). Some modern sparkplugs do not have a glazed center insulator that when used with modern E10 fuels can foul easily and not fire. We have used an Autolite 386 with good results. For more info on wires and connectors please see Plug and Wire RX. It is helpful to apply an anti seize agent to the threads.

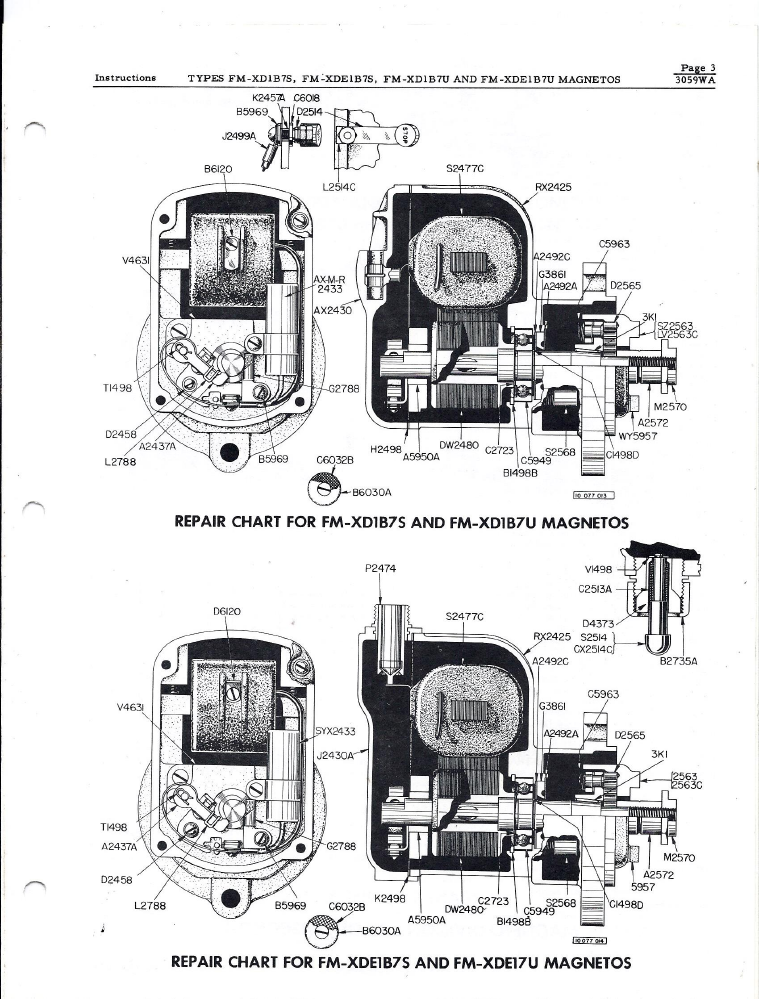

Check the condenser for leakage, then capacity. it should come in around 0.2MFD. Not to much condenser trouble with these. A condenser for a Delco distributor will work fine. If the points still have meat(Contact material) on them by all means use them. Use a diamond file or stone to get the jagged edges off the polish to a mirror finish and they will stay clean. Make sure that the contact surfaces line up with each other when closed. Bend the stationary point as needed and/or add a spacer to the breaker lever shaft. If polishing the points shows a reddish copper like tinge, the contact material is gone and the points need replacing. When testing the coil, best to remove it from the housing as when pulsing the coil with the tester, it may discharge the magnets in the rotor. Be mindfull when removing the two 1/4-20 slotted setscrews holding the coil in place. They are very hard, brittle and one side of the slot can break off causing discouraging words and a trip to the milling machine for a Helicoil insert. Use a good fitting screwdriver and if the screws do not come out easily, heat the top of the housing with a propane torch. Sometimes the screws have a heat sensitive thread retainer that will let go and the heat will make the housing grow bigger than the screw. It is not usually possible to tell by looking at the coil or using an ohmmeter to see if it is good or not. Use an actual coil tester for a valid test.

The coils (part# S2477C) used by these magnetos look like those used by the multi cylinder counterparts but are coloured black and made different. I do not know all the answeres to this issue.