There are no products listed under this category.

Shop by Category

-

Wico Magneto RX

- AX Magneto Brochure

- B Magneto RX

- F Series: F,FG,FGM,FGS

- A Magneto RX

- Condenser Information

- EK Magneto Rx

- LD and H Magneto RX

- OC Wico Magneto

- R Magneto Ignitor RX

- XH and XHD Magneto RX

- AH Wico magneto Rx

- AP Magneto RX

- C Magneto RX

- FW Series: Flywheel Magneto Service Info

- H1 Magneto RX

- J4 Manual

- JEM Manual

- PR Magneto RX

- Wico Magneto 1946 Catalog

-

Wico Magneto Application Information

- XVD-4 and XVD-6

- Bendix

- Berling Magnetos

-

Bosch, American Bosch, and Robert Bosch

-

American Bosch

-

Am Bosch Mags Ca 1945 MJA MJB MJC MVA MJK

- MRA Magneto American Bosch

- MRF American Bosch Magneto

- DU1,DU2,DU4..Ad nauseum Bosch Catalog 50

- Flywheel Magnetos by American Bosch

- Impulse Coupler RX

- Instruction Book & Agents 1925 Am Bosch

- Service Manual American Bosch Magneto 1928

- ZR4 For Ingersoll Rand Compressor

- ZR4 ZR6 Instruction Manual

- AB 33 and some mumblings on the AB34

- Application Information

- AT4 AT6 Bosch Magneto Instruction Parts Manual

- B4 + B6 Manual

- Bosch Magneto Service Parts List 1922

- DU Service Manual

- FX1 American Bosch Magneto Parts List

- Home of the Bosch Magneto

- MRD Am Bosch Magneto Service Manual

- MVA American Bosch Magneto Instruction Manual

- U1 U2 U4 U6 Debut Whatsa Matter U?

- ZR4 Service manual

-

Am Bosch Mags Ca 1945 MJA MJB MJC MVA MJK

- Bosch

- Robert Bosch

-

American Bosch

-

Edison Magneto

-

Eisemann

- CM4/CT4 Eisemann Magneto Instructions

-

Flywheel Magnetos by Eisemann

- Eisemann 61-D flywheel magneto

- Eisemann 61Cflywheel Mag

- eisemann 61DA Flywheel magneto

- Eisemann 61DC flywheel magneto

- Eisemann 61DE Flywheel magneto

- Eisemann 61DF Flywheel magneto

- Eisemann 61DH Flywheel magneto

- Eisemann 61NA flywheel magneto

- Eisemann 62-D Flywheel magneto

- Eisemann 72C Flywheel Magneto

- Eisemann 72D Maytag Magneto

- Eisemann 72DA Maytag Magneto Service

- Eisemann 82-D and 82-F Flywheel Mags

- M4G6 Eisemann Magneto Generator

- AM Series

- Automatic Spark Control Early

- CM-4 Caterpillar Magneto Service + Parts Manual

- CT-4 Caterpillar Magneto Service & Parts Manual

- EB

- ED EU EA

- Eisemann Catalog 1920

- Eisemann Catalog with Accessories

- Eisemann catalog 1915

- Eisemann- Caterpillar Parts Info

- EM Dual

- EM for Model T Ford

- G0 G1 G2 Service and Parts Manual

- G4

- GL Series Service & Parts Manual

- GL1 GL2 GLF1 GLF2

- GL4 GL2H

- GN6 Edition 3 Manual

- GN6 Edition 4

- GR4 Ed 2 magneto parts&Service manual

- GS Series

- GV Series Service and Parts Manual

- GV-4 GV-2H GV-2Q

- GV-6 Eisemann magneto

- RC/RT Series

-

Fairbanks Morse

- Fairbanks Morse Illustrated parts 1983 Sec 4

- Fairbanks Morse Magneto Application Information

- Fairbanks Morse Model "R" RX

- FM FM-H FM-K FMO FM-OH Heavy Duty Series RX

- FM-J1A.. FM-J1B.. Radio Shld 9864A

- FMJ Series Parts List 1947 Bulletin 9846B

- FMJ1A Instructions 1947 Bulletin 2888B

- FMJ1A.. FMJ1B.. 1947 Bulletin 2864B

- FMJ2 Series 2854C

- FMJ4A,B Instructions 1942 Bulletin 2846A

- FMJH Series: Mercury/Disston/Kiekhafer 9871A

- FMJV4B Wisconsin V4 Engine

- FMX. Series: AKA the Updated FMJ series

- Magnetizing Fairbanks Morse Magnetos

- RV RX

- Heinze AX & BX Magneto

- Ignition and Truck Profits

- International Harvester Magneto Rx

-

K-W Ignition Company Magnetos

- K-W Ignition Magneto Instruction Book 3Rd Ed

- K-W Low tension Magnetos catalog 19

- K-W Model J Magneto Manual

- K-W Model T and TK Magneto Instruction Book

- K-W O F Oscillating Magneto Manual

- K-W T TK TU TUK Magneto Catalog Ed 8

- K-W T TK TU TUK Magneto Manual Edition 6

- KW Magneto Promo What Makes Tractor Go?

- Perfection Magneto Company

- Pittsfield type B Magneto

- Remy

- Simms Magneto

- Simms Motor Units Catalog 1940

-

Splitdorf

- C Magneto Specifications

- C Magneto manual

-

Dixie and Aero Magnetos

- Dixie 46 246 462 Magneto Parts List

- Aero 448 449 648 649 Magneto

- Aero AE Magneto Manual

- Aero Magneto Catalog 1925

- Dixie 235 Oscillating Magneto

- Dixie 40 42 and 44 Magneto Manual N-404A 1919

- Dixie 46 Magneto Manual N-403C 1919

- Dixie 8 Cylinder Magnetos #83-86

- Dixie Aero Service Info

- Dixie Magneto Model 60 and 63 Catalog 1915

- Dixie Splitdorf Magneto Catalog N-401

- Splitdorf 46T and EM Impulse Starter

- Splitdorf Dixie M1 & M2 Magneto

- NS-1-2550 Magneto parts List

- NS-2 Magneto Parts list

- NS-4 Magneto parts List

- S-2 Magneto Parts List

- S-4 Magneto parts List

- SS-4 Magneto Parts List

- SS-6 Magneto Parts List

- SS-6-2 Magneto Parts List

- SSO Magneto Parts List

- AE

- Cross Country On Motorcycle

- NS Motorcycle Magneto Manual

- S NS SS B Magneto Service Manual

- Splitdorf Apelco Starting Lighting

- Splitdorf catalog 1910

- Splitdorf catalog 51 1913

- Splitdorf Magneto catalog 52 1914

- Splitdorf Magneto catalog 53 Models EU & EV

- Splitdorf Magneto catalog 57 1914

- Splitdorf Wiring Diagrams 1914

- U & V Splitdorf Magneto manual 1912

- Sumter Magneto Rx

- Webster

-

Wico Magneto RX

- AX Magneto Brochure

- B Magneto RX

- F Series: F,FG,FGM,FGS

- A Magneto RX

- Condenser Information

- EK Magneto Rx

- LD and H Magneto RX

- OC Wico Magneto

- R Magneto Ignitor RX

- XH and XHD Magneto RX

- AH Wico magneto Rx

- AP Magneto RX

- C Magneto RX

- FW Series: Flywheel Magneto Service Info

- H1 Magneto RX

- J4 Manual

- JEM Manual

- PR Magneto RX

- Wico Magneto 1946 Catalog

- Wico Magneto Application Information

- XVD-4 and XVD-6

- Bendix

- Berling Magnetos

- Bosch, American Bosch, and Robert Bosch

- Edison Magneto

-

Eisemann

- CM4/CT4 Eisemann Magneto Instructions

- Flywheel Magnetos by Eisemann

- M4G6 Eisemann Magneto Generator

- AM Series

- Automatic Spark Control Early

- CM-4 Caterpillar Magneto Service + Parts Manual

- CT-4 Caterpillar Magneto Service & Parts Manual

- EB

- ED EU EA

- Eisemann Catalog 1920

- Eisemann Catalog with Accessories

- Eisemann catalog 1915

- Eisemann- Caterpillar Parts Info

- EM Dual

- EM for Model T Ford

- G0 G1 G2 Service and Parts Manual

- G4

- GL Series Service & Parts Manual

- GL1 GL2 GLF1 GLF2

- GL4 GL2H

- GN6 Edition 3 Manual

- GN6 Edition 4

- GR4 Ed 2 magneto parts&Service manual

- GS Series

- GV Series Service and Parts Manual

- GV-4 GV-2H GV-2Q

- GV-6 Eisemann magneto

- RC/RT Series

-

Fairbanks Morse

- Fairbanks Morse Illustrated parts 1983 Sec 4

- Fairbanks Morse Magneto Application Information

- Fairbanks Morse Model "R" RX

- FM FM-H FM-K FMO FM-OH Heavy Duty Series RX

- FM-J1A.. FM-J1B.. Radio Shld 9864A

- FMJ Series Parts List 1947 Bulletin 9846B

- FMJ1A Instructions 1947 Bulletin 2888B

- FMJ1A.. FMJ1B.. 1947 Bulletin 2864B

- FMJ2 Series 2854C

- FMJ4A,B Instructions 1942 Bulletin 2846A

- FMJH Series: Mercury/Disston/Kiekhafer 9871A

- FMJV4B Wisconsin V4 Engine

- FMX. Series: AKA the Updated FMJ series

- Magnetizing Fairbanks Morse Magnetos

- RV RX

- Heinze AX & BX Magneto

- Ignition and Truck Profits

- International Harvester Magneto Rx

-

K-W Ignition Company Magnetos

- K-W Ignition Magneto Instruction Book 3Rd Ed

- K-W Low tension Magnetos catalog 19

- K-W Model J Magneto Manual

- K-W Model T and TK Magneto Instruction Book

- K-W O F Oscillating Magneto Manual

- K-W T TK TU TUK Magneto Catalog Ed 8

- K-W T TK TU TUK Magneto Manual Edition 6

- KW Magneto Promo What Makes Tractor Go?

- Perfection Magneto Company

- Pittsfield type B Magneto

- Remy

- Simms Magneto

- Simms Motor Units Catalog 1940

-

Splitdorf

- C Magneto Specifications

- C Magneto manual

- Dixie and Aero Magnetos

- NS-1-2550 Magneto parts List

- NS-2 Magneto Parts list

- NS-4 Magneto parts List

- S-2 Magneto Parts List

- S-4 Magneto parts List

- SS-4 Magneto Parts List

- SS-6 Magneto Parts List

- SS-6-2 Magneto Parts List

- SSO Magneto Parts List

- AE

- Cross Country On Motorcycle

- NS Motorcycle Magneto Manual

- S NS SS B Magneto Service Manual

- Splitdorf Apelco Starting Lighting

- Splitdorf catalog 1910

- Splitdorf catalog 51 1913

- Splitdorf Magneto catalog 52 1914

- Splitdorf Magneto catalog 53 Models EU & EV

- Splitdorf Magneto catalog 57 1914

- Splitdorf Wiring Diagrams 1914

- U & V Splitdorf Magneto manual 1912

- Sumter Magneto Rx

- Webster

RC/RT Series

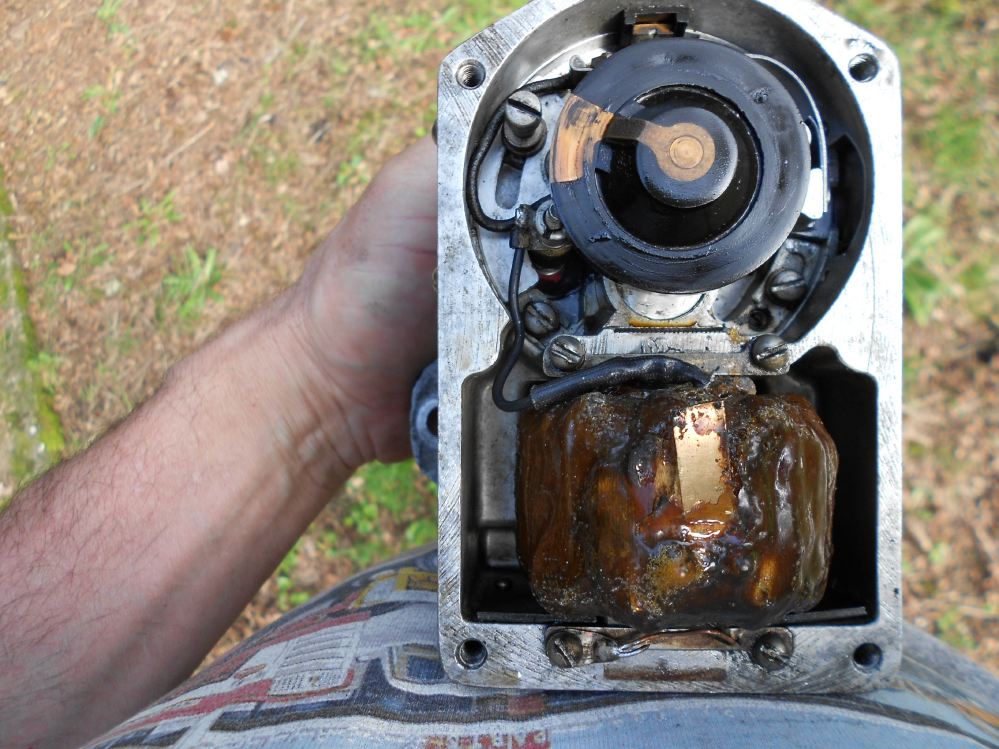

The RC/RT series were sold as replacements and are probably best known as OEM for many Caterpillar Diesel 2 cylinder pony motors. Some 4 and 6 cylinder units were also made. They are very hot and troublefree with proper care. The pony motor mags came in many configurations, clockwise,anticlockwise, firing at 90 degrees, and 180 degrees.This means be carefull when swapping distributor caps. Some were gear driven, fortunately most were impulse coupled. Some were mounted horizontally and some even upside down.

If things are not complicated enough with combinations of all of the above, some had carbon brush rotors and others jump spark design. The jump spark distributors were equipped with a ventilated cap and/or housing as when the spark jumps to its proper plug post it creates its own private lightning storm. This private lightning storm reacts naturally occuring diatomic atmospheric oxygen O2(Means two molecules stuck together for non chemistry majors) into O3 or ozone. That is the fresh outdoorsy smell after a lightning storm. It reacts with atmospheric nitrogen (N2) and water vapour which makes HNO3 or nitric acid which is corrosive. Carbon brush distributors do not need ventilation but should be cleaned of carbon dust about every year with a brake or electric motor cleaner and a soft brush to prevent shorts. Be sure the cap is completely dry before reassembly and use because many cleaners are explosive and may cost you a new cap made of unobtainium or very expensive. it is also helpfull ro clean out air vents in the housing and cap in case muddaubers have taken up residence. Be mindful of the position of the mag when in service as the air vents should point downward when replaced to keep mositure out.

This example has a brush type distributor and plates on the side of the housing where vent covers would be if it were a jump spark design.

Points are set at .020. If you take one off a tractor or find one it is a good idea to take it apart, wash the bearings and relube with an electric motor grease or a black molybdenum product. Most studies show modern petroleum base grease will last up to 30 years with proper storage. Most of the iron we yard out of the boondocks has been sitting for far longer and not properly stored to say the least. Dab some grease on the cam the size of a match head while you are at it. If the cam has any rust, give it a good polish with some crocus cloth and a straight edge. The screws that fasten the points spring are a metric size, but standard. New springs can be made of readily available blue tempered spring steel.

Always check the condenser for leakage. If no leakage them check capacity, it should come in at about 0.2MFD. If it is one of the left hand 180 degree gear driven mags for a D2 or D4 beware of loose bearings in the engine, this will break the magneto shaft every time due to excessive radial force from loose engine bearings. Expensive lesson!

Here is a parts list from a factory service manual to help keep your mag in top shape. The grounding switch stud is often broken off. For safety's sake replace it if so. Use a brass screw and a stainless steel nut. Make sure that the wire from the stud connecting to the stop switch is sound.