There are no products listed under this category.

Shop by Category

Plug, Wire, Condenser RX

Here is a common source of torment and grief for restorers:

Early ignition systems used wires with a stranded copper center conductor and a thick 7MM diameter rubber outer jacket. Some had an outer cloth braid for appearance and durability. Very early wires were larger yet, often 9MM. Copper is ductile, flexible, easy to solder and a superb conductor and all was well.

Enter the modern age with oil filled ignition coils,high output ignition systems and electronics and we have a new breed of ignition wire. Modern wires often have a non metallic conductor with internal resistance to be compatible with modern ignition systems but are a Big NO NO with early ignition systems, especially with magnetos. The internal resistance of these wires and many spark plugs dissipates ignition power and stresses early design coils causing poor performance and failure. Some auto parts jobbers we have encountered were not aware of this.

The best wire we have found to use is of the braided metallic conductor type.Some are copper, some are steel. We prefer a copper stranded product like Borg Warner type MW11 (We found it at O'Reilly's Auto Parts). It is flexible, ductile, solders easily and is easy to route.Steel wire works fine too. It uses a modern Hypalon jacket that resembles the early rubber jacket. Some of the early gas engine restoration parts stores offer the early cloth covered wire as well.

The spool on the left is available at Napa Auto Parts and is a stranded steel wire. The spool in the center is a Hypalon insulated Borg Warner MW11 or Standard CC7N product with stranded copper conductors found at O'reilly Auto parts. The spool on the right is an attractive original appearing 7MM braided copper conductor product available in different colours found in the Gas Engine Magazine offered by Lee W. Pedersen.

Here are some of the available connections to use on ignition wires. Most magnetos of later design used a brass end(Like the 727008 Napa Belden product) that pokes into the end of the wire and crimps to the sides of it. You can also slide a rubber boot over the wire (Like the BWD CT506). If the boot does not slide easily over the rubber wire, use soapsuds on the wire then slip the boot on. Some magnetos accept ends like the CT500 found on distributors. If the terminal does not have a feature that pokes into the wire to make connection to the conductor you may strip the wire about 1/2 the length of the terminal, fold the bare center conductor wire over the outer wire jacket then crimp the terminal over it on the wire. The 90 degree ends with a boot like BWD CT516 go on fairly easily when the wire and boot is wetted with soapsuds. Poke the wire into the boot, pull it out of the boot the rest of the way with needle nose pliers, then install and crimp the terminal end and pull the wire with the terminal installed back inside the boot. Boots are a great idea on exposed protruding sparkplugs on outboards, scooters and Cat D2 and D4 pony motors. They keep the plug connection dry and can prevent a dose of shock therapy if you brush against it.

The attractive authentic appearing terminals on the right were found in the Gas Engine Magazine offered by Lee W. Pedersen. They are made to crimp on. We typically strip the wire 1/8" or so, then push the bare braid through the hole in front, flatten and solder, then crimp for a positive connection when cool.

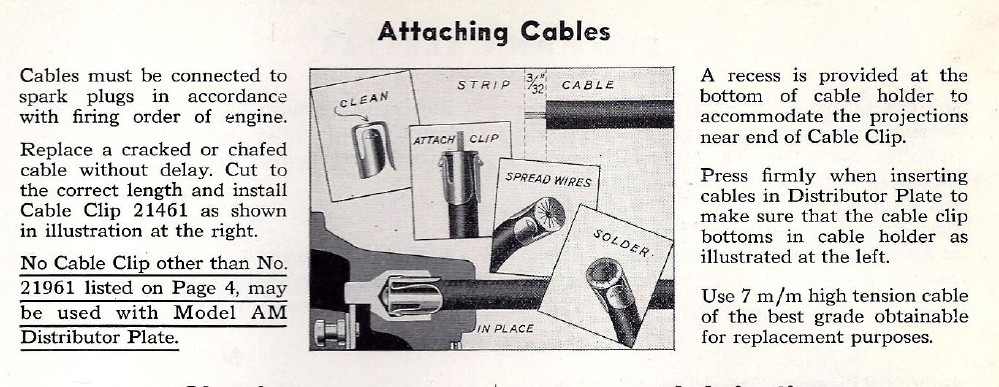

Here are some good words from an early Eisemann service manual. We do this on all plug wire ends. It makes a positive mechanical and electrical connection and prevents the end from getting stuck in the distributor cap. It is best to make the solder connection then crimp the terminal on the wire when cool.

Here is a terminal installed on an attractive 9MM spark plug wire for an oilfield engine. The wire is stripped and tinned on the end to prevent fraying. This should only be done near the end and not areas where the wire may flex as it will more readily break.This works well when the wire is wrapped around a screw or stud. Brass spark plug wire terminals for Model T Fords are available from many antique Ford parts suppliers. These work and show well on larger 9MM wires like early systems used. These attractive terminals were offered by Snyder's Antique Auto Parts of New Springfield, Ohio. I prefer to solder the conductor to the terminal, then let it cool to the touch before crimping. Polish the area to be soldered with emery cloth and use a non corrosive solder. You may use 60/40 or better yet 63/37 rosin cored solder. The 63/37 alloy has more tin and melts at a lower temperature than 60/40. A slip joint plier works well for crimping spark plug wire terminals. When you need to strip spark plug wires, use a safety razor to make a clean initial cut,carefull not to get too deep and cut the conductors, then grab the wire strippers to remove the insulation. The initial cut with the razor makes a clean cut through the cloth jacket.

Condenser Rx: Everything you may wish to know and then some.

Condensers or capacitors for the electrical engineering types are critical components in many early magneto and distributor ignition systems. They serve to intensify the spark and prevent arcing at the points when functioning properly. They are in essence two metal plates with wires attached and a non conducting material between them as an insulator or dielectric that collect and store a charge between the plates. They can fail as an open by losing connection to one or both plates and showing no capacity under test. They can also fail as a short by acting like the two lead wires are connected directly together. A common failure is leakage where the insulation media between the plates partly breaks down as an insulator (often by absorbing moisture) causing a device that fails to hold a charge. They can also fail intermittently (very annoying!!) and any combination of the above. Whenever testing a condenser, check for leakage first.Very important. A leaky device should be replaced and may give overstated capacity readings especially with a digital capacitance meter. When replacing a condenser, always remove or disconnect the defective condenser. Early condensers used wax and paper as an insulator that usually spells trouble especially after spending much time in the soggy Northwest even when sitting on a shelf indoors.

Modern condensers use improved insulation and sealing technology with plastic polymer insulation and hermetically sealed cases. Many early ignition condensers are about .15-0.25MFD capacity at 400 Volts or so. Here are some examples of modern readily available automotive/industrial engine condensers. These should be readily available at your local parts jobber.

.

The top two devices are used by Ford and should be readily available. The one on the left is for a Pinto and the device on the right is used in a Ford truck with a 360 V8 and likely others. These work well in tight spaces where there is not room for the side bracket. The PT521 is used by many GM applications and is very readily available and affordable. If a smaller capacitance is needed as in some two stroke ignition systems and some Edison Splidorf mags the JC-35 and the 31-1800 can be used. The 31-1800 aka 1800 is an excellent fit for the Maytag twin with that pesky Eisemann 72D and 72DA magneto. These are used by some of the earlier Lawnboy and other power products.

If there is not the space or shape to use an automotive device these industrial electronic devices can be used. They were originally made by Sprague and are known as "Orange Drops" in the electronics/electrical engineering profession. Presently there are two types of Orange Drops. The ones to use for ignition circuits are the devices designed for spike currents. Orange drops are hermetically sealed with epoxy and nearly indestructible.

The voltage rating is stamped on the device. If possible use the highest voltage rating that will still physically fit. A 400 volt device will work well and replace many early paper devices. Earlier devices have the capacitance stamped on and later versions have the value less the decimal imprinted on the lower left next to the letter J. The device on the lower left is rated at .224 Microfarad at 400 Volts.

The device in the upper right corner rated at .474 MFD and works very well in buzz coil installations. Model T Ford types are well acquainted with those annoying buzz coils. Nearly all as found flea market model T buzz coils will have bad condensers. Toss the early paper condensers and use a modern device and all will be well.

These components are readily available from electronics suppliers as AVNET, Newark Electronics,URS Electronics,Mouser Electronics, TUBESNMORE and many others.

Here is an Rx for a bad condenser in the base of a wound armature for an International E4A. These condensers do not improve with age, especially left outside in the soggy Northwest. The bottom was unsoldered and the old condenser removed. One capacitor lead is soldered to the case (ground) and the other fitted with insulating sleeve and connects to the points and ungrounded coil primary.

The part above is from an Eisemann GV4 wound armature that was a victim of sticky goo that glued the armature to the poleshoes and a mighty crank. The steel shaft turned in the brass armature endcap and chewed into the condenser mounted in the base.

Many modern spark plugs also have internal resistors and are to be avoided in early ignition systems. Some modern plugs also have a porcelain center insulator that is not glazed and tends to collect deposits, foul easily and not clean off in early engines that start and or run with a rich mixture and overlubricate. Some of our antique engines simply do not run long or hot enough during shows to clean off the plug deposits. The problem is usually with the center porcelain insulator. A coating of soot and other deposits on it will short out the spark before it gets to the plug. Sometimes the conductive deposits are not visible.

Sometimes brake or electric motor cleaner will help clean the soot off fouled plugs. If a bead blaster is used to clean the plugs, be sure to get all the abrasive residue out before reinstalling. We like the early design take apart plugs of days past and supplied by the Model A and Model T Ford parts houses for old stationary engines. They can be taken apart and cleaned with a plastic scrubbing pad and bathtub/sink cleaner and reassembled with anti seize.Bead blasting may destroy a glaze on the center electrode insulator. You may check for leaks by squirting oil around the porcelain center and looking for bubbles while engine is running. Anti seize compound is a good idea when installing sparkplugs, especially when they are threaded into aluminum. They can seize and take the threads out with the plugs. Care is also due to not overtighten and to keep excess anti seize compounds away from the plug electrodes as they are often conductive and can cause a short.

For many two stroke applications using a 1/2" pipe thread needing a fairly hot plug like dragsaws,outboards and some Maytags we use an Autolite 3095. There is also reproduction of the early Champion X take apart plug with 1/2" pipe threads available from many Model T Ford parts dealers. The early Champion 33 was a large 2 part plug branded "Gas Engine Special" designed for the early stationary engines. The Champion 34 gas Engine special had a longer reach and was used extensively by Maytag.

For the 7/8" spark plugs the Model A Ford parts dealers also have the Champion 3X which is a take apart 7/8" plug.This is best for flathead or single cylinder engines. The Autolite 3076 is a fairly hot 7/8" thread plug that is inexpensive, readily available and seems to stay clean and foul less with the modern fuel these days. It works well in overhead valve engines where the plugs are in pockets in the head and space is a concern. It is recomended for the earlier John Deere letter series tractors and the early McCormick-Deerings. The 3077 is a hotter 7/8" plug.

For 18MM plug applications with magneto ignition like the letter series International and John Deere tractors the Autolite 3116 and gapped at .025" is recomended. This is a non resistor plug with a 1/2" reach and a medium/hot heat range and works well with many other installations, especially with a magneto.

For the letter series John Deere and International tractors equipped with distributors requiring an 18MM plug, the Autolite 386 and the hotter 388 gapped at .030 are recomended.

For 14MM applications like the John Deere LA the 216 Autolite gapped at .025" is recomended. this is a 14MM non resistor plug with a 1/2" reach.

Always refer to the engine manual for proper thread,gap, reach and heat range whenever possible to find the right plug. Life gets tedious, don't it?

More on spark plugs to follow: