There are no products listed under this category.

Shop by Category

-

Wico Magneto RX

- AX Magneto Brochure

- B Magneto RX

- F Series: F,FG,FGM,FGS

- A Magneto RX

- Condenser Information

- EK Magneto Rx

- LD and H Magneto RX

- OC Wico Magneto

- R Magneto Ignitor RX

- XH and XHD Magneto RX

- AH Wico magneto Rx

- AP Magneto RX

- C Magneto RX

- FW Series: Flywheel Magneto Service Info

- H1 Magneto RX

- J4 Manual

- JEM Manual

- PR Magneto RX

- Wico Magneto 1946 Catalog

-

Wico Magneto Application Information

- XVD-4 and XVD-6

- Bendix

- Berling Magnetos

-

Bosch, American Bosch, and Robert Bosch

-

American Bosch

-

Am Bosch Mags Ca 1945 MJA MJB MJC MVA MJK

- MRA Magneto American Bosch

- MRF American Bosch Magneto

- DU1,DU2,DU4..Ad nauseum Bosch Catalog 50

- Flywheel Magnetos by American Bosch

- Impulse Coupler RX

- Instruction Book & Agents 1925 Am Bosch

- Service Manual American Bosch Magneto 1928

- ZR4 For Ingersoll Rand Compressor

- ZR4 ZR6 Instruction Manual

- AB 33 and some mumblings on the AB34

- Application Information

- AT4 AT6 Bosch Magneto Instruction Parts Manual

- B4 + B6 Manual

- Bosch Magneto Service Parts List 1922

- DU Service Manual

- FX1 American Bosch Magneto Parts List

- Home of the Bosch Magneto

- MRD Am Bosch Magneto Service Manual

- MVA American Bosch Magneto Instruction Manual

- U1 U2 U4 U6 Debut Whatsa Matter U?

- ZR4 Service manual

-

Am Bosch Mags Ca 1945 MJA MJB MJC MVA MJK

- Bosch

- Robert Bosch

-

American Bosch

-

Edison Magneto

-

Eisemann

- CM4/CT4 Eisemann Magneto Instructions

-

Flywheel Magnetos by Eisemann

- Eisemann 61-D flywheel magneto

- Eisemann 61Cflywheel Mag

- eisemann 61DA Flywheel magneto

- Eisemann 61DC flywheel magneto

- Eisemann 61DE Flywheel magneto

- Eisemann 61DF Flywheel magneto

- Eisemann 61DH Flywheel magneto

- Eisemann 61NA flywheel magneto

- Eisemann 62-D Flywheel magneto

- Eisemann 72C Flywheel Magneto

- Eisemann 72D Maytag Magneto

- Eisemann 72DA Maytag Magneto Service

- Eisemann 82-D and 82-F Flywheel Mags

- M4G6 Eisemann Magneto Generator

- AM Series

- Automatic Spark Control Early

- CM-4 Caterpillar Magneto Service + Parts Manual

- CT-4 Caterpillar Magneto Service & Parts Manual

- EB

- ED EU EA

- Eisemann Catalog 1920

- Eisemann Catalog with Accessories

- Eisemann catalog 1915

- Eisemann- Caterpillar Parts Info

- EM Dual

- EM for Model T Ford

- G0 G1 G2 Service and Parts Manual

- G4

- GL Series Service & Parts Manual

- GL1 GL2 GLF1 GLF2

- GL4 GL2H

- GN6 Edition 3 Manual

- GN6 Edition 4

- GR4 Ed 2 magneto parts&Service manual

- GS Series

- GV Series Service and Parts Manual

- GV-4 GV-2H GV-2Q

- GV-6 Eisemann magneto

- RC/RT Series

-

Fairbanks Morse

- Fairbanks Morse Illustrated parts 1983 Sec 4

- Fairbanks Morse Magneto Application Information

- Fairbanks Morse Model "R" RX

- FM FM-H FM-K FMO FM-OH Heavy Duty Series RX

- FM-J1A.. FM-J1B.. Radio Shld 9864A

- FMJ Series Parts List 1947 Bulletin 9846B

- FMJ1A Instructions 1947 Bulletin 2888B

- FMJ1A.. FMJ1B.. 1947 Bulletin 2864B

- FMJ2 Series 2854C

- FMJ4A,B Instructions 1942 Bulletin 2846A

- FMJH Series: Mercury/Disston/Kiekhafer 9871A

- FMJV4B Wisconsin V4 Engine

- FMX. Series: AKA the Updated FMJ series

- Magnetizing Fairbanks Morse Magnetos

- RV RX

- Heinze AX & BX Magneto

- Ignition and Truck Profits

- International Harvester Magneto Rx

-

K-W Ignition Company Magnetos

- K-W Ignition Magneto Instruction Book 3Rd Ed

- K-W Low tension Magnetos catalog 19

- K-W Model J Magneto Manual

- K-W Model T and TK Magneto Instruction Book

- K-W O F Oscillating Magneto Manual

- K-W T TK TU TUK Magneto Catalog Ed 8

- K-W T TK TU TUK Magneto Manual Edition 6

- KW Magneto Promo What Makes Tractor Go?

- Perfection Magneto Company

- Pittsfield type B Magneto

- Remy

- Simms Magneto

- Simms Motor Units Catalog 1940

-

Splitdorf

- C Magneto Specifications

- C Magneto manual

-

Dixie and Aero Magnetos

- Dixie 46 246 462 Magneto Parts List

- Aero 448 449 648 649 Magneto

- Aero AE Magneto Manual

- Aero Magneto Catalog 1925

- Dixie 235 Oscillating Magneto

- Dixie 40 42 and 44 Magneto Manual N-404A 1919

- Dixie 46 Magneto Manual N-403C 1919

- Dixie 8 Cylinder Magnetos #83-86

- Dixie Aero Service Info

- Dixie Magneto Model 60 and 63 Catalog 1915

- Dixie Splitdorf Magneto Catalog N-401

- Splitdorf 46T and EM Impulse Starter

- Splitdorf Dixie M1 & M2 Magneto

- NS-1-2550 Magneto parts List

- NS-2 Magneto Parts list

- NS-4 Magneto parts List

- S-2 Magneto Parts List

- S-4 Magneto parts List

- SS-4 Magneto Parts List

- SS-6 Magneto Parts List

- SS-6-2 Magneto Parts List

- SSO Magneto Parts List

- AE

- Cross Country On Motorcycle

- NS Motorcycle Magneto Manual

- S NS SS B Magneto Service Manual

- Splitdorf Apelco Starting Lighting

- Splitdorf catalog 1910

- Splitdorf catalog 51 1913

- Splitdorf Magneto catalog 52 1914

- Splitdorf Magneto catalog 53 Models EU & EV

- Splitdorf Magneto catalog 57 1914

- Splitdorf Wiring Diagrams 1914

- U & V Splitdorf Magneto manual 1912

- Sumter Magneto Rx

- Webster

-

Wico Magneto RX

- AX Magneto Brochure

- B Magneto RX

- F Series: F,FG,FGM,FGS

- A Magneto RX

- Condenser Information

- EK Magneto Rx

- LD and H Magneto RX

- OC Wico Magneto

- R Magneto Ignitor RX

- XH and XHD Magneto RX

- AH Wico magneto Rx

- AP Magneto RX

- C Magneto RX

- FW Series: Flywheel Magneto Service Info

- H1 Magneto RX

- J4 Manual

- JEM Manual

- PR Magneto RX

- Wico Magneto 1946 Catalog

- Wico Magneto Application Information

- XVD-4 and XVD-6

- Bendix

- Berling Magnetos

- Bosch, American Bosch, and Robert Bosch

- Edison Magneto

-

Eisemann

- CM4/CT4 Eisemann Magneto Instructions

- Flywheel Magnetos by Eisemann

- M4G6 Eisemann Magneto Generator

- AM Series

- Automatic Spark Control Early

- CM-4 Caterpillar Magneto Service + Parts Manual

- CT-4 Caterpillar Magneto Service & Parts Manual

- EB

- ED EU EA

- Eisemann Catalog 1920

- Eisemann Catalog with Accessories

- Eisemann catalog 1915

- Eisemann- Caterpillar Parts Info

- EM Dual

- EM for Model T Ford

- G0 G1 G2 Service and Parts Manual

- G4

- GL Series Service & Parts Manual

- GL1 GL2 GLF1 GLF2

- GL4 GL2H

- GN6 Edition 3 Manual

- GN6 Edition 4

- GR4 Ed 2 magneto parts&Service manual

- GS Series

- GV Series Service and Parts Manual

- GV-4 GV-2H GV-2Q

- GV-6 Eisemann magneto

- RC/RT Series

-

Fairbanks Morse

- Fairbanks Morse Illustrated parts 1983 Sec 4

- Fairbanks Morse Magneto Application Information

- Fairbanks Morse Model "R" RX

- FM FM-H FM-K FMO FM-OH Heavy Duty Series RX

- FM-J1A.. FM-J1B.. Radio Shld 9864A

- FMJ Series Parts List 1947 Bulletin 9846B

- FMJ1A Instructions 1947 Bulletin 2888B

- FMJ1A.. FMJ1B.. 1947 Bulletin 2864B

- FMJ2 Series 2854C

- FMJ4A,B Instructions 1942 Bulletin 2846A

- FMJH Series: Mercury/Disston/Kiekhafer 9871A

- FMJV4B Wisconsin V4 Engine

- FMX. Series: AKA the Updated FMJ series

- Magnetizing Fairbanks Morse Magnetos

- RV RX

- Heinze AX & BX Magneto

- Ignition and Truck Profits

- International Harvester Magneto Rx

-

K-W Ignition Company Magnetos

- K-W Ignition Magneto Instruction Book 3Rd Ed

- K-W Low tension Magnetos catalog 19

- K-W Model J Magneto Manual

- K-W Model T and TK Magneto Instruction Book

- K-W O F Oscillating Magneto Manual

- K-W T TK TU TUK Magneto Catalog Ed 8

- K-W T TK TU TUK Magneto Manual Edition 6

- KW Magneto Promo What Makes Tractor Go?

- Perfection Magneto Company

- Pittsfield type B Magneto

- Remy

- Simms Magneto

- Simms Motor Units Catalog 1940

-

Splitdorf

- C Magneto Specifications

- C Magneto manual

- Dixie and Aero Magnetos

- NS-1-2550 Magneto parts List

- NS-2 Magneto Parts list

- NS-4 Magneto parts List

- S-2 Magneto Parts List

- S-4 Magneto parts List

- SS-4 Magneto Parts List

- SS-6 Magneto Parts List

- SS-6-2 Magneto Parts List

- SSO Magneto Parts List

- AE

- Cross Country On Motorcycle

- NS Motorcycle Magneto Manual

- S NS SS B Magneto Service Manual

- Splitdorf Apelco Starting Lighting

- Splitdorf catalog 1910

- Splitdorf catalog 51 1913

- Splitdorf Magneto catalog 52 1914

- Splitdorf Magneto catalog 53 Models EU & EV

- Splitdorf Magneto catalog 57 1914

- Splitdorf Wiring Diagrams 1914

- U & V Splitdorf Magneto manual 1912

- Sumter Magneto Rx

- Webster

- Home

- Magneto Rx:

- Bosch, American Bosch, and Robert Bosch

- American Bosch

- Am Bosch Mags Ca 1945 MJA MJB MJC MVA MJK

- MJA

MJA

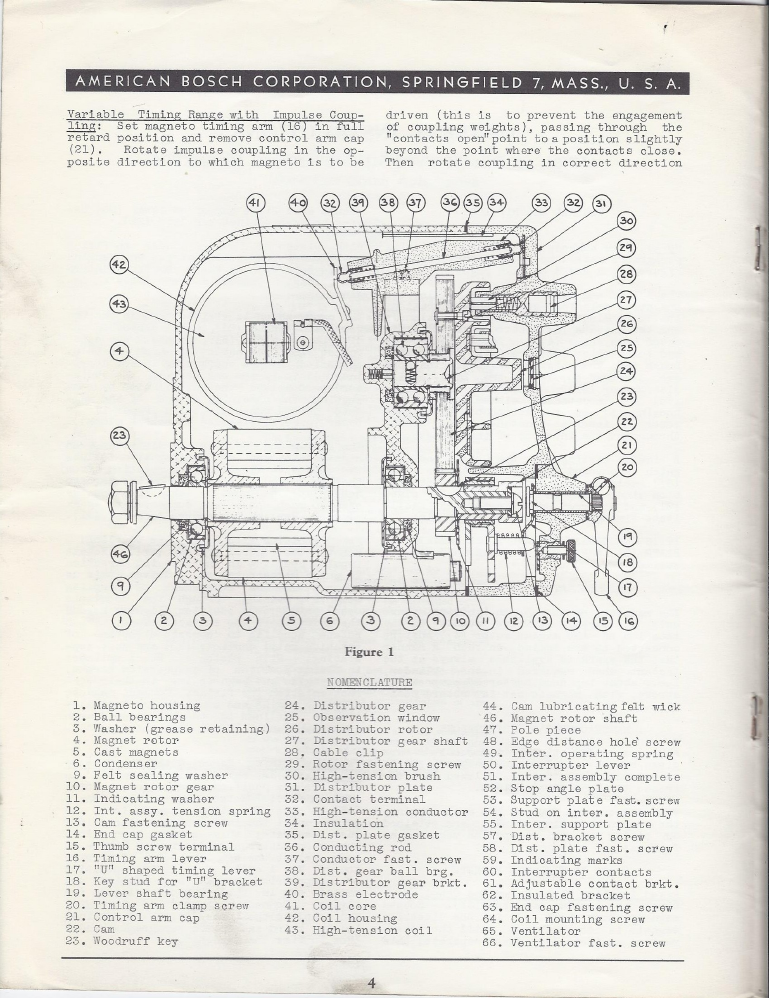

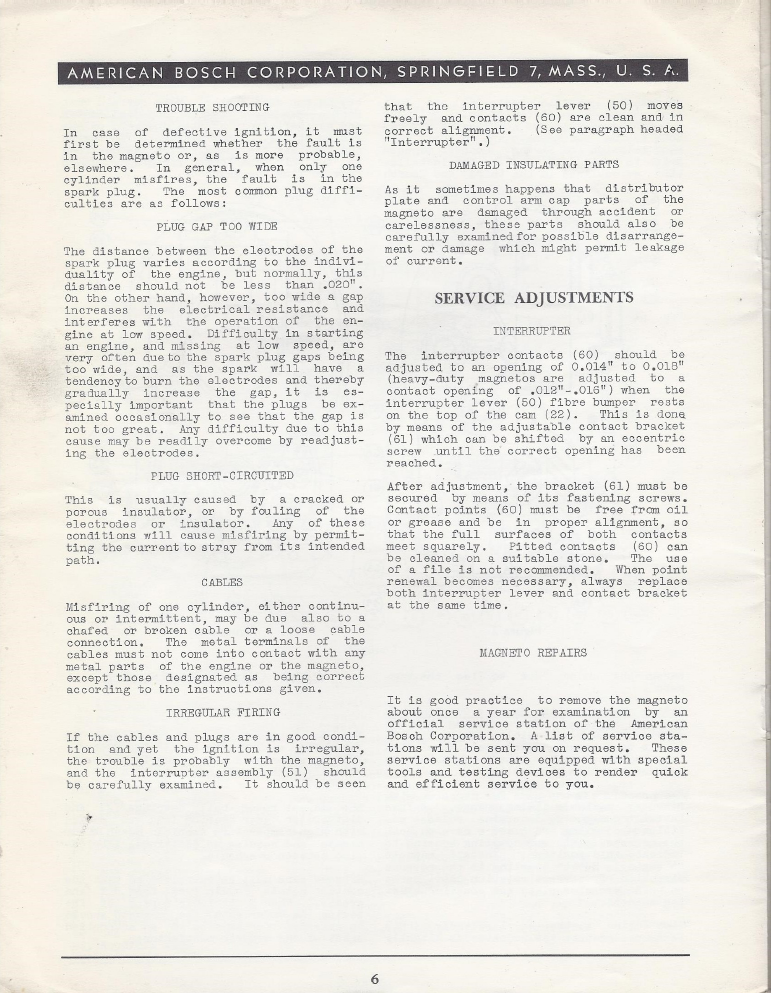

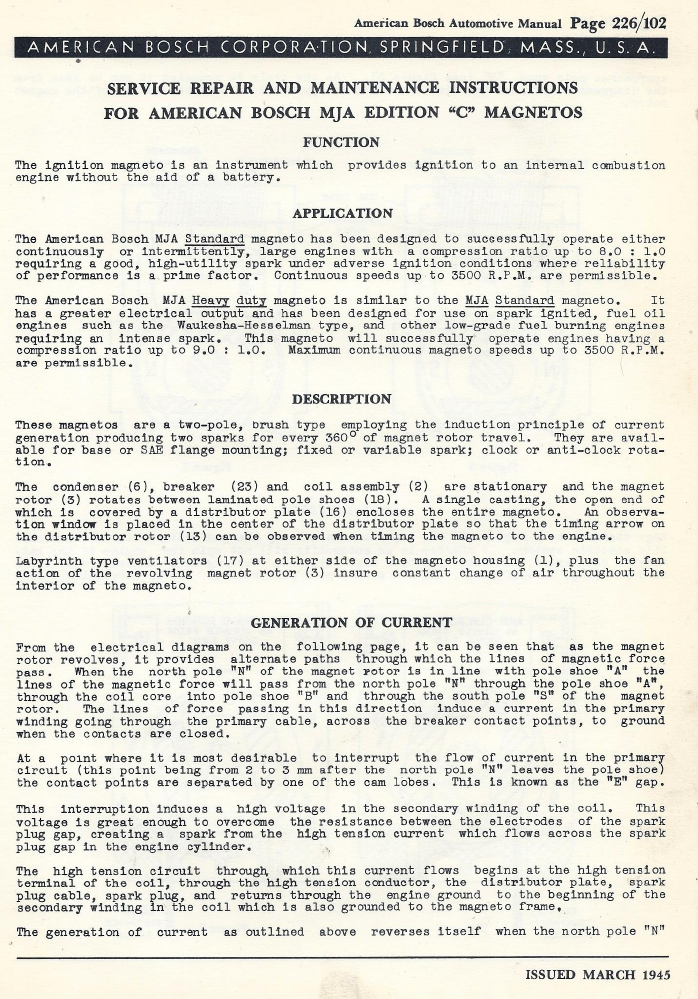

The MJA is one of the biggest and baddest of the American Bosch MJ series. Very robust and reliable.

Here are some images from a factory owner's brochure to share to keep yours alive and well. There is some helpful factory service manual info presented as well.

Your magneto is probably out of warranty.

The hex headed screw that fastens the point spring has 10-32 threads and a Hex head that is 5MM across the flats FYI. If there is still

meat left on the point contact surfaces after dressing and polishing, by all means use them. When installing new points, make sure that

the contact surfaces line up with each other for maximum surface contact. A fine diamond lap like an Easy Lap is great for getting the jagged

edges off the points, then dress to a mirror finish with something very fine like a stone or Cratex stick. Points that are smooth will stay clean much

longer than rough. We usually aim for .015" of point clearance. If the point contacts are far out of alignment, sometimes you can slide the

phenolic pivot bushing up or down in the point lever to correct. If you find a barn or field fresh unit, always best to pull it apart, wash everything out

and repack the bearings. For the points cam, put a dab of grease the size of a match head on. An electric motor grease or a good molybdenum

product that will stay put is desired. oil and grease on the contact surfaces is a big nono.

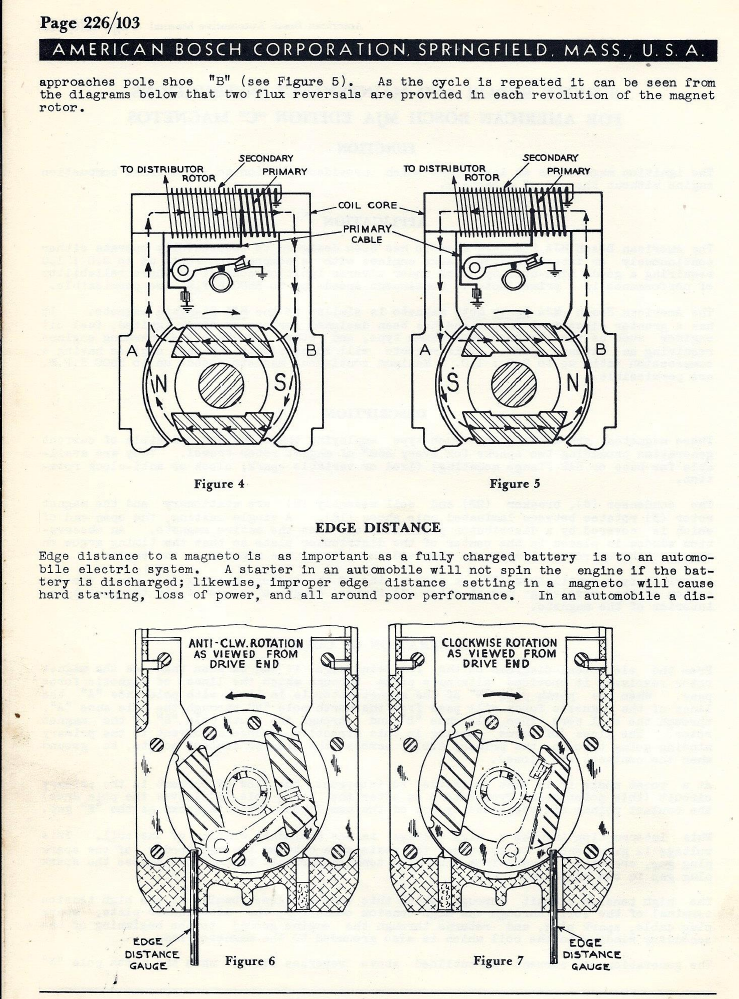

Here is some info on setting and checking edgegap. Optimal performance and best spark is where breaking the electrical circuit occurs at an ideal interval after breaking the magnetic circuit. This interval is edgegap. If you remove the breaker plate you can see that there is a fair range of rotational positions it can be secured in. If it is an adjustable timing model, place the timinmg lever in full advance when setting the edge gap. If the edgegap is not close to right, we will have a wimpy mag. Check the edgegap after the points are properly set.

A drill bit works well for this task.